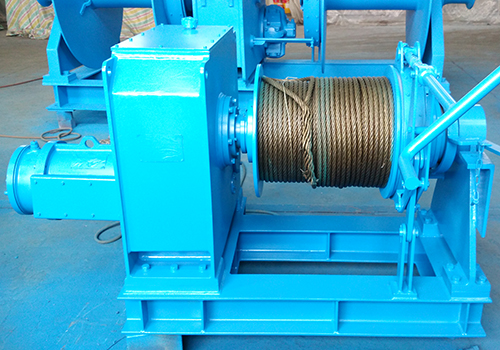

Marine winches are mainly used on ships. As one of the main machinery of ships, daily maintenance is a headache.

The first 3-5 years of the marine winch can basically fully cope with the impact of the environment. With the passage of time, coupled with the corrosion or improper operation caused by daily use and special offshore environments, the life of the marine winch will always decrease a lot. The daily maintenance of marine winches has become an important task, and the daily maintenance and maintenance methods of marine winches are what EME company will talk about today.

In fact, maintenance and maintenance are daily tasks in two directions. Maintenance is mainly aimed at surface problems, such as the paint surface of marine winches; such as the daily lubrication and maintenance of marine winches, such as regular oiling, etc., while maintenance is just the opposite, more The main thing is that it requires experienced or veteran operators to disassemble and debug, and it requires after-sales assistance of the machinery or strictly follows the operation manual to operate. It is undeniable that a large mechanical equipment such as a marine winch requires a very complete and suitable maintenance plan. , and this maintenance program requires professional knowledge for both the executor and the requester.

Today, let's talk about the maintenance points of marine winches in detail:

1. Oil pollution

Oil pollution seems to be a common problem of all large-scale machinery, and it is also a headache for most machinery operators. After all, it is impossible for large-scale machinery and equipment to not use oil, especially marine winches. The friction coefficient of the brake discs and brake shoes of marine winches will increase. Due to oil pollution, it will drop sharply, which will affect the braking torque and cause serious equipment and personal accidents.

In normal maintenance, it is necessary to check whether there is oil pollution on the working surface of the brake disc and brake shoe of the marine winch. It must be cleaned in time. At the same time, it is necessary to observe the abnormality in the working state in time. Installation maintenance reduces the risk of equipment damage.

2. Marine winch oil

After long-term use, the oil will produce foam and sediment, but because it is difficult to be found immediately in the oil tank of the equipment, it must be replaced within six months according to the normal cycle. At the same time, it is also necessary to observe the oil in daily use. Check whether the oil level is within the range of the oil level indicator line to ensure that the machine will not cause potential danger due to lack of oil or abnormal oil gauge.

3. Marine winch repair

In the early running-in stage of the marine winch, it is necessary to dismantle and repair the brake or hydraulic station, but when repairing, it must be noted that in addition to turning off the power of the solenoid valve, the valve core must be locked with a locking device, which can ensure There will be no accidents during the repair process. In particular, it should be said here that more than two people must be present during the dismantling and repair process to avoid emergencies that cannot be dealt with immediately.

4. Inspection and maintenance of marine winches during operation

During the operation of the marine winch, a special person must check the wear of the brake shoe of the pneumatic winch.

Assuming that the wear of the brake shoe reaches 2 and the displacement of the coil spring exceeds 1, the operation should be stopped in time for adjustment and inspection, so as not to affect the braking torque, and the wear switch and disc of the brake shoe should also be checked before restarting. Whether the reed exhaust switch is working properly, these are the preparations required before the second start.

5. Regular inspection of the reducer for marine winches

The marine winch should check the pneumatic winch reducer regularly. If it is found that the sound and vibration of the reducer are abnormal, the temperature rises, and the surface of the teeth gradually appears pitting or large-scale scratches, it should stop the operation in time, and immediately contact the after-sales service for disassembly, inspection and treatment. In this way, the life of marine winch equipment can be extended while reducing the risk factor.